In China, the textile industry ranks fourth in terms of industrial wastewater discharge, with printing and dyeing wastewater accounting for 80%, while the reuse rate of wastewater and dyes is less than 10%. According to data, the daily discharge of dyeing wastewater in China alone is as high as 3-4 million cubic meters. If all of this wastewater is recycled and reused, it is equivalent to saving 20% of the daily domestic water consumption of residents nationwide. Industrial wastewater treatment and reuse will be an important direction for the treatment of printing and dyeing wastewater in the future. (Data source: China Environmental Protection Online)

The printing and dyeing industry is the main source of pollution in the textile industry, including multiple processes such as desizing, refining, bleaching, silk finishing, dyeing, printing, and finishing. Printing and dyeing wastewater has the characteristics of large water volume, high concentration of organic pollutants, deep color, high alkalinity, large water quality changes, and complex composition, making it one of the more difficult industrial wastewater to treat. The traditional printing and dyeing wastewater treatment process is mainly based on "pretreatment+AO", among which the biochemical stage includes hydrolysis contact oxidation, hydrolysis activity, SBR and other technologies. The COD of the discharged water is between 150-300mg/l. Most printing and dyeing wastewater treatment projects are facing upgrading or expansion.

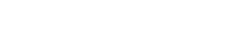

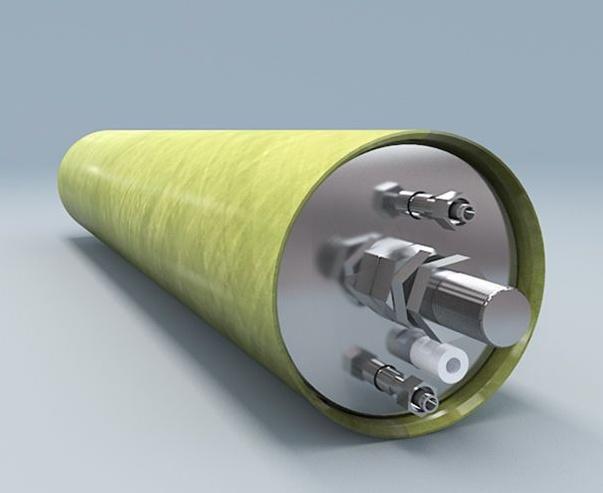

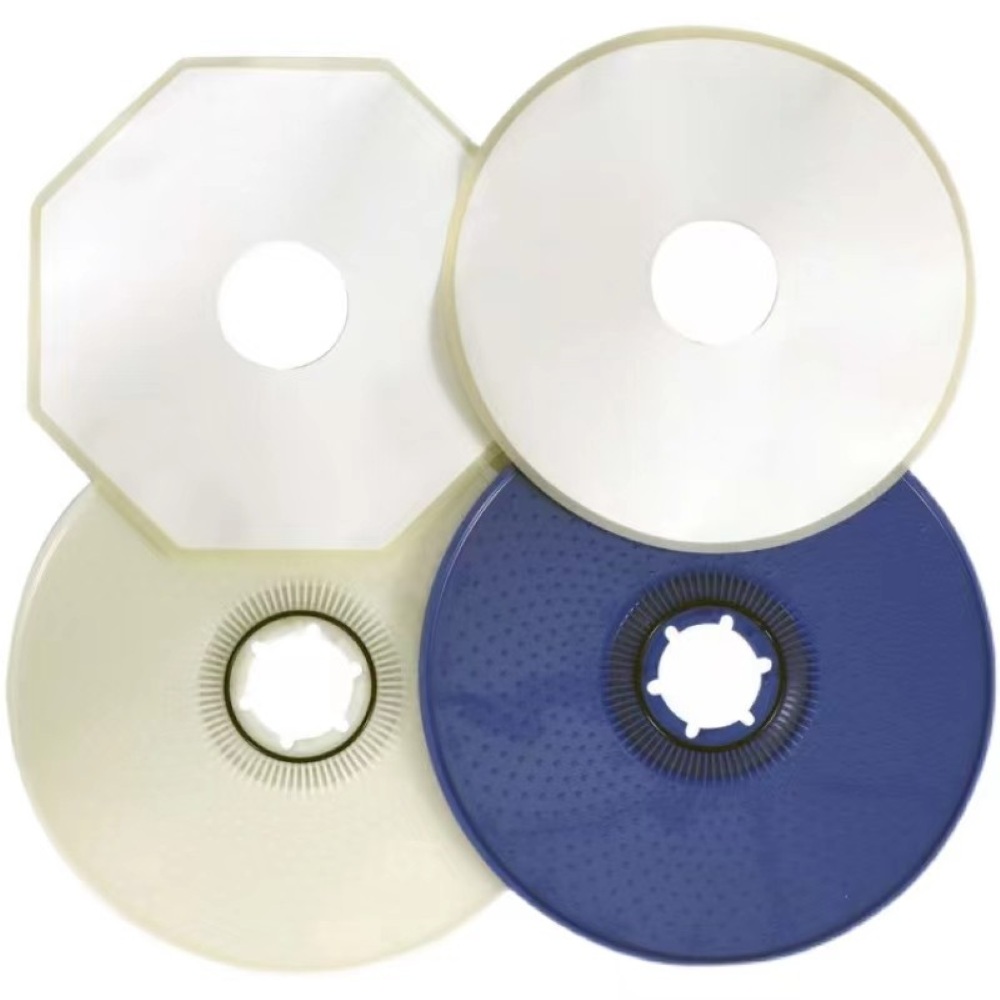

In recent years, the DTRO membrane system has received increasing attention and application in the field of upgrading and transforming printing and dyeing wastewater due to its characteristics of small footprint, good effluent quality, strong shock load resistance, and low sludge production. Due to the complex pollutants present in printing and dyeing wastewater, especially fiber like substances that are prone to aggregation, cleaning is difficult. The special design of the guide plate, with a 4mm open flow channel for the membrane and guide plate, enables turbulent water flow during the filtration process. At the same time, the feed liquid will turn 180 ° after a very short distance in the membrane column, allowing the feed liquid to mix again. The DTRO membrane system basically does not have fiber entanglement problems.

The development of textile printing and dyeing technology has led to an increasingly complex composition of printing and dyeing wastewater, and the difficulty of wastewater treatment has also escalated. The DTRO membrane system has excellent performance, simple pretreatment, can adapt to various water sources, and reliable water quality.