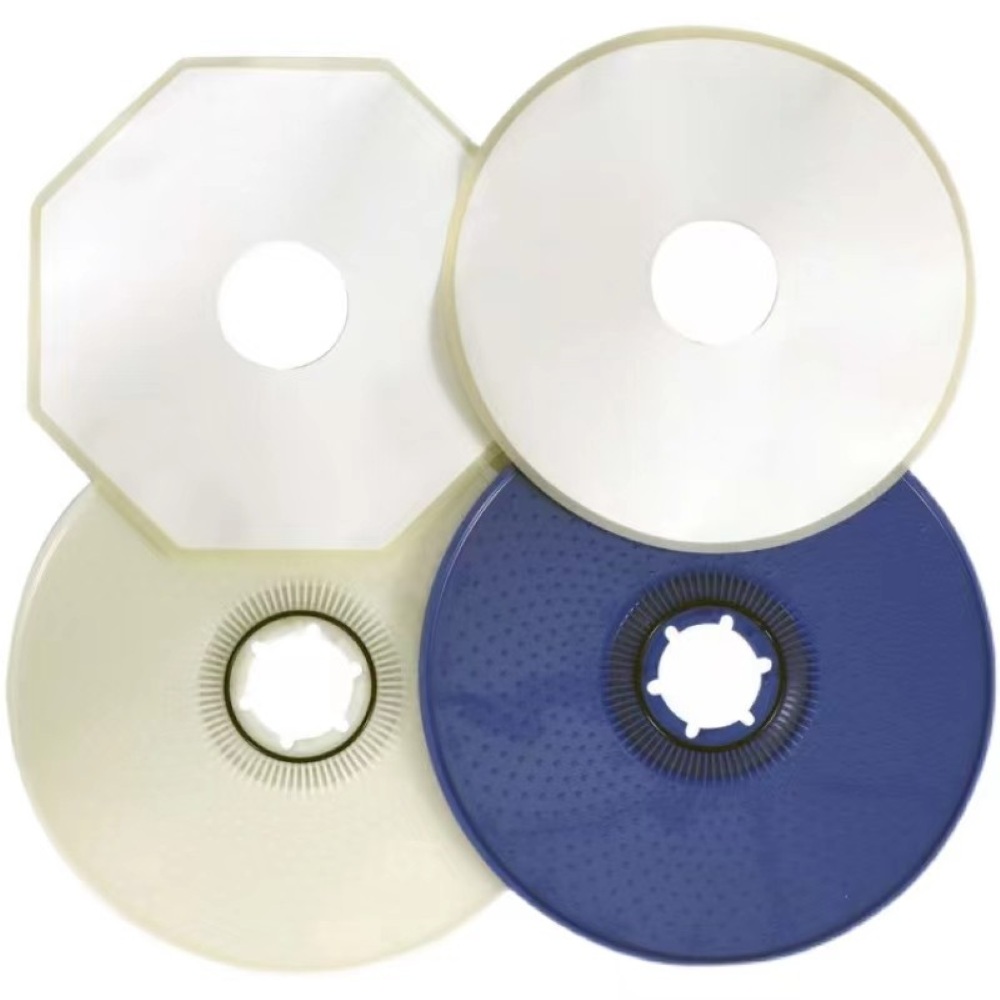

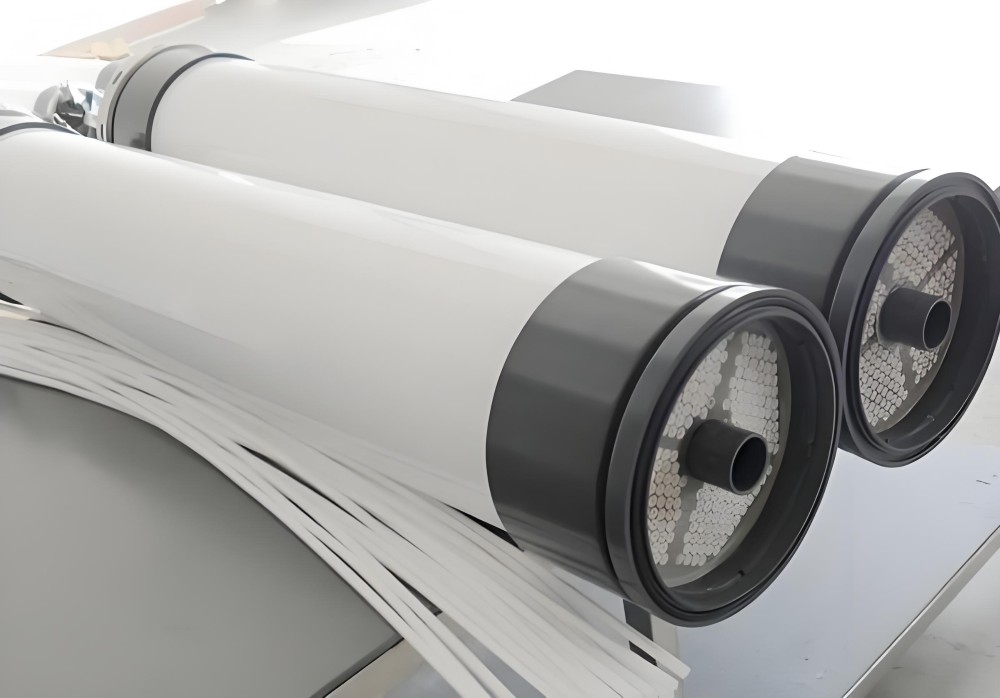

1) The core of tubular microfiltration equipment is microporous membrane, which is a porous membrane made of ultra-high molecular weight polymer with a pore size range of 0.1-1.0 microns. Combined with micro flocculation technology, the raw water flows through the filtration membrane under a pressure of 0.1-1.8 kg/cm2, which can separate suspended particles, colloids, organic macromolecules, bacteria, microorganisms, etc. in the raw water, purifying the water.

2) As the filtration time increases, particles are trapped on the membrane surface or in the membrane pores, forming a layer of filter cake. In order to maintain a certain flow rate, it is necessary to increase the driving pressure. When the pressure reaches a certain value, the retention layer on the membrane must be backwashed to remove the filter cake and restore the ability of the filter membrane.

The tubular microfiltration equipment adopts an air wash+water wash backwash system, which disinfects the filter membrane while backwashing. Generally, it automatically backwashs every 30-60 minutes, with a backwash time of 60-90 seconds each time.

3) After a long period of operation, some pollutants or particles in the water are more firmly adsorbed by the filter membrane, and cannot be completely washed away during backwashing, but accumulate. At this time, chemical cleaning is needed to react the pollutants with the chemical cleaning solution, detach the solution from the membrane, and then remove them through backwashing to restore the filtration performance of the membrane. The time interval for chemical cleaning is generally 10-20 days.

4) The fully enclosed microfiltration system includes all electronic components such as raw water pumps, frequency converters, pressure sensors, electromagnetic flow meters, automated instruments and meters, online raw water and filtered water turbidity meters, programmable logic controllers (PLCs), monitoring machines, etc. The equipment has two switchable operating modes: automatic and manual. Under normal circumstances, the operation and backwashing of the equipment are fully automated.

Characteristics of tubular membrane technology

The tubular membrane filtration technology replaces traditional processes such as dosing, flocculation, and sedimentation to produce drinking water through membrane filtration, which is a technological innovation in the field of drinking water production. Compared with conventional water treatment equipment, this tubular microfiltration water treatment technology and equipment have the following advantages:

Small footprint

1) The tubular microfiltration water treatment technology directly filters water to achieve further purification of water quality. Water plants built with this technology have lightweight and compact equipment, occupying 20-30% of the land area and 15-20% of the building load of conventional water plants. They can be directly built on clear water tanks or arranged in multiple layers to save land or space, which is particularly suitable for the renovation and capacity expansion of old water plants; In the northern regions with long freezing periods, it is usually necessary to cover or insulate the structures of water plants. If a tubular microfiltration water plant is used, it can not only save a lot of construction funds but also reduce the energy consumption required for insulation.

Easy installation of complete equipment

2) All tubular microfiltration equipment is assembled water treatment equipment, which has been assembled and debugged before leaving the factory. After purchase, users can quickly transport it to the site for installation and debugging. A water plant with a daily output of tens of thousands of tons can be built within five months, which can shorten the construction period. For water plants with rapid water consumption growth, it can be designed at once, and then assembled tubular microfiltration equipment can be added according to the increase in water consumption, which can avoid the large amount of capital occupied by one-time construction.

Fully automated control

3) The tubular microfiltration plant has a high degree of automation, strong adaptability to changes in raw water quality (turbidity less than 3500NTU), stable treated water quality, and can meet the increasing demand for drinking water quality.

Low management costs

4) Under the same level of automation, tubular microfiltration water plants have a shorter construction period, smaller footprint, lower operating and management costs after completion, and better water quality treatment compared to conventional water plants.

5) The device is small in size, light in weight, and can be flexibly assembled and moved.

6) Due to the absence of chlorine, by-products generated by chlorine (such as trihalides with strong carcinogenic effects) are avoided.

7) Easy to operate, high degree of automation, and few operators.

8) Chemical cleaning is simple, requires less medication, has low cost, and has a long service life for the membrane.

9) The complete set of water treatment equipment can be industrially produced, greatly reducing the amount of civil engineering required for water plants.

Application scope of tubular microfiltration membrane water treatment equipment

This tubular microfiltration and ultrafiltration water treatment equipment can be used for the preparation of high-purity water in urban, rural, institutional, electronic industries, and various industrial wastewater treatments. In addition, the application scope of tubular microfiltration water treatment equipment is as follows:

1) Small and medium-sized equipment is suitable for oil exploration, mining, military, field construction, villages and factories in remote mountainous areas far from urban water supply networks, self owned water plants for large inland ships, and deep treatment of tap water in advanced water use areas within cities.

2) Due to its excellent water quality and operational stability, it can be applied to water treatment in the chemical, pharmaceutical and health, food, electronic components, knitting and dyeing industries.

3) The construction of large and medium-sized water plants in cities, as well as the upgrading or capacity expansion of old water plants.

4) Can be used as pre-treatment and final treatment equipment for high-purity water preparation such as reverse osmosis, ultrafiltration, ion exchange, electrodialysis, etc.