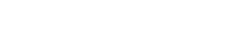

1、 Disc tube membrane module

DT membrane technology, also known as disc tube membrane technology, is divided into two categories: DTRO (disc tube reverse osmosis) and DTNF (disc tube nanofiltration), and is a patented membrane separation equipment. Its membrane module construction is completely different from traditional roll type membranes.

1. Raw liquid flow channel

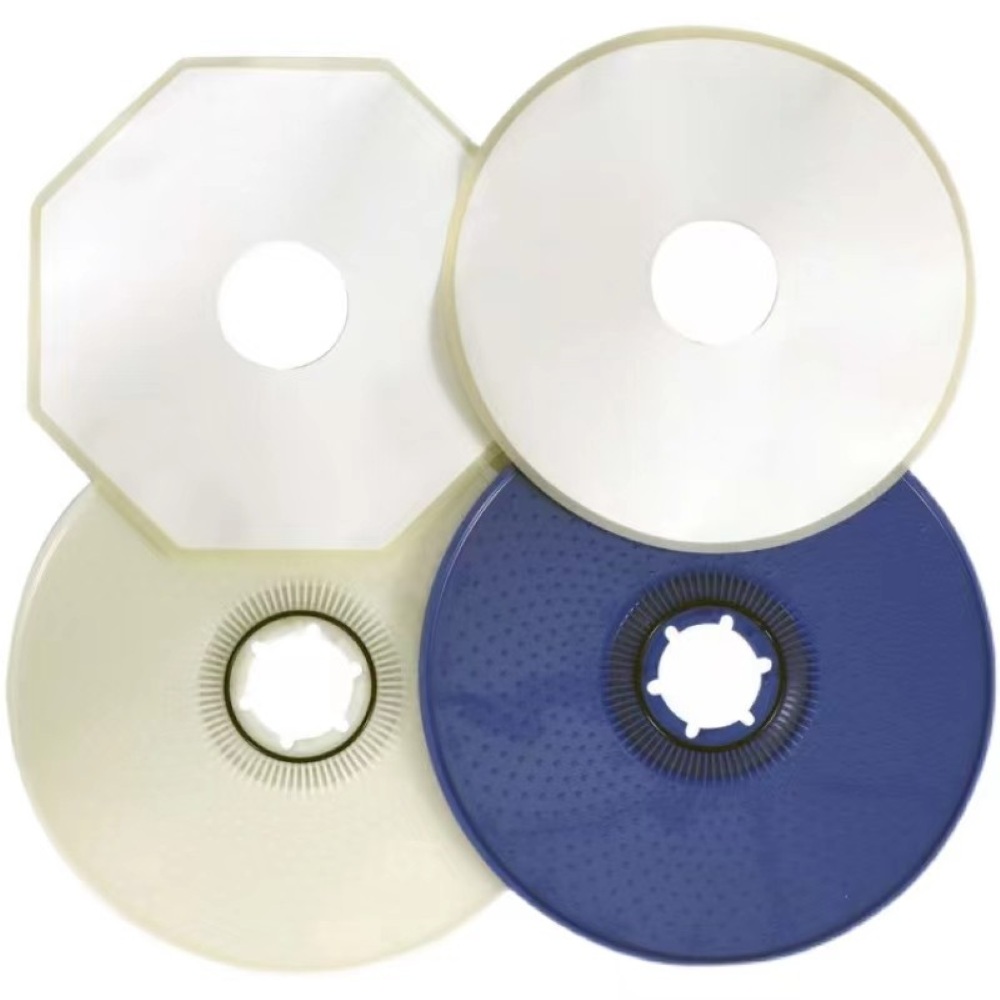

The disc tube membrane module has a patented flow channel design form, which adopts an open flow channel. The feed liquid enters the pressure vessel through the inlet and flows from the channel between the guide plate and the shell to the other end of the module. At the flange at the other end, the feed liquid enters the guide plate through 8 channels. The processed liquid flows quickly through the filter membrane at the shortest distance, then reverses 180 ° to the other membrane surface, and flows into the next guide plate from the groove in the center of the guide plate, thus forming a double "S" - shaped path from the circumference of the guide plate to the center of the circle, then to the circumference, and finally to the center of the circle on the membrane surface. The concentrated liquid flows out from the flange at the feed end.

The distance between the two guide plates of the DT component is 4mm, and there are protrusions arranged in a certain way on the surface of the guide plates. This special hydraulic design creates turbulence when the treatment liquid flows through the surface of the filter membrane under pressure and collides with protrusions, increasing the permeation rate and self-cleaning function, effectively avoiding membrane blockage and concentration polarization, and successfully extending the service life of the membrane; It is also easy to clean the scale on the membrane during cleaning, ensuring that the disc tube membrane assembly is suitable for treating wastewater with high turbidity and high sand content, and can adapt to more adverse inlet conditions.

2. Through the liquid channel

The filter membrane consists of two concentric circular reverse osmosis membranes, with a layer of filamentous support sandwiched between them, allowing the purified water passing through the membrane to quickly flow towards the outlet. The outer ring of these three-layer ring-shaped materials is welded using ultrasonic technology, while the inner ring is open and serves as a clean water outlet.

The permeate flows along the filamentous support in the middle of the membrane to the permeate channel on the periphery of the central pull rod, and the O-ring seal on the guide plate prevents raw water from entering the permeate channel; The distance from the membrane to the center of the permeate is very short, and it is equal for all filter membranes within the component.

2、 Two stage DTRO process

The two-stage DTRO process is based on the application of a disc tube reverse osmosis membrane. Its core technology lies in the unique structural form of the disc tube reverse osmosis membrane, which makes it possible for the reverse osmosis membrane to directly treat high concentration wastewater. It is a stable and reliable treatment technology with the characteristics of low investment, high self-control, easy operation and maintenance, low operating costs, and stable and continuous compliance with emission requirements. The specific details are as follows:

(1) The process is simple and compact, and the equipment set is standardized. As shown in the diagram of the two-stage DTRO complete set of equipment, the complete set of equipment integrates sand filtration system and security filter for pretreatment, membrane components for reverse osmosis, high-pressure pump, circulation pump, cleaning water tank for system cleaning, MCC cabinet and PLC cabinet for equipment power supply and control, etc.

In addition, standardized complete sets of equipment such as raw water tanks, pump valves, etc. are also used for acid adjustment of raw water and alkali callback of effluent, all of which are processed, installed, and debugged in the factory; Once the Yunda site is lifted into place, it can be debugged and put into operation with a short cycle.

(2) Strong process stability, simple maintenance, and low energy consumption. Due to the limited factors affecting the retention rate of the membrane system, the effluent quality of the system is very stable and not affected by factors such as biodegradability and nitrogen ratio; The DT membrane module used in the process adopts standardized design, which is easy to disassemble and maintain. Opening the DT module allows for easy inspection and maintenance of any filter membrane and other components. Maintenance is simple, and when the number of components is insufficient, the module allows for fewer membranes and guide plates to be installed without affecting the use of the DT membrane module.

DT membrane components effectively prevent membrane fouling, reduce membrane fouling, and extend the lifespan of reverse osmosis membranes. The special structure and hydraulic design of DT make the membrane assembly easy to clean, and the flux recovery after cleaning is very good, thereby extending the membrane life. Practical engineering has shown that in the treatment of leachate solution, the service life of the first stage DT membrane can be as long as 3 years or even longer, and when connected to other treatment facilities (such as MBR), the service life can be as long as 5 years or more, which is not achievable for general reverse osmosis treatment systems.

In this process, there is no need to achieve the final removal of pollutants, only for separation, therefore, the operating energy consumption is greatly reduced; Any individual component inside the DT component is allowed to be replaced separately. The filtration part is assembled from multiple filtration membranes and guide disks. When the filtration membrane needs to be replaced, it can be replaced individually. For membranes with good filtration performance, they can still be used, which greatly reduces the cost of membrane replacement.

(3) The effluent quality is good, and the reverse osmosis membrane has a very high removal rate for various pollutants. The effluent quality is good, and the current main applications are single-stage (connected in series to the biochemical effluent) and two-stage DTRO, which can fully meet various reuse or discharge standards.

(4) Flexible operation: As a set of physical separation equipment, the DTRO system is very flexible in operation, and can operate continuously or intermittently. It can also adjust the series parallel connection mode of the system to meet the requirements of water quality and quantity.

(5) The construction period is short, and the debugging and start-up are fast. The core components of the two-stage DTRO process are assembled in the factory, accompanied by supporting factory buildings and water tank construction. The scale is small and the construction speed is fast. After the equipment arrives at the site, it only takes about two weeks to complete the installation and debugging work.

(6) The process system has a high degree of automation and simple operation. It is fully automated and equipped with a complete monitoring and control system. The PLC can automatically adjust according to sensor parameters and issue alarm signals in a timely manner to protect the system. Operators only need to search for error codes and troubleshoot according to the operating manual, and there is no high requirement for their experience.

(7) Small footprint, the core equipment of the two-stage DTRO process is integrated installation, and the ancillary structures and facilities are also some small structures with a very small footprint.

(8) Recyclable, the core component of the two-stage DTRO process is the DTRO integrated equipment, which is easy to move and install. The overall service life of the equipment is over 20 years, and it can be moved to other projects for continued use after one project is completed.

3、 Process flow and description

2. Process description

(1) Preprocessing

Due to different factory conditions and pre-treatment processes, high concentration wastewater has a complex composition and contains various insoluble salts such as calcium, magnesium, barium, and silicon. These insoluble inorganic salts are highly concentrated after entering the reverse osmosis system. When their concentration exceeds the solubility under these conditions, scaling will occur on the membrane surface. Adjusting the raw water can effectively prevent scaling of carbonate inorganic salts, so pH adjustment of the raw water is necessary before entering reverse osmosis.

The effluent from the regulating tank is pumped into the raw water tank of the reverse osmosis system, where acid is added to adjust the pH. The effluent from the raw water tank is pressurized by the pump and then enters the quartz sand filter. The number of sand filters is determined according to the specific processing scale, with a filtration accuracy of 50 μ m. There are pressure gauges at both the inlet and outlet ends of the sand filter. When the pressure difference exceeds 25 bar, a backwash procedure must be performed. The frequency of backwashing the sand filter depends on the suspended solids content in the incoming water. For general wastewater, the backwashing cycle of the sand filter is about 100 hours. For raw water with low SS values, if the pressure difference does not exceed 25ba after running the sand filter for 100 hours, backwashing must also be carried out to avoid excessive compaction and compaction of quartz sand. The first arrival time is used as the automatic activation time for sand filter backwashing. Sand filter water washing adopts raw water cleaning; Air washing uses compressed air generated by a rotary vane compressor.

After sand filtration, the water enters the core filter. For the leachate treatment system, due to the high content of calcium, magnesium, barium and other easily scaling ions and silicates in the raw water, these salts are prone to supersaturation on the concentrate side after being highly concentrated by DT membrane components. Therefore, according to the actual water quality, a certain amount of scale inhibitor should be added before the core filter to prevent the occurrence of silicon scale and sulfate scale. The specific addition amount is determined by the analysis of the raw water quality. The scale inhibitor should be diluted with 20 times water before use. The core filter provides the last protective barrier for the membrane column, with an accuracy of 10 μ m. Similarly, the number of core filters is determined based on the specific processing scale, just like sand filters.

(2) Process flow of two-stage DTRO system

This system is a two-stage reverse osmosis system. The first stage of reverse osmosis requires water to enter from the core filter, while the second stage of reverse osmosis processes the first stage of permeate water.

The effluent from the raw water storage tank is supplied to the reverse osmosis equipment by a pump, while the sand filter booster pump provides pressure to the raw water. There is one sand filter in total, and there are pressure gauges at both the inlet and outlet ends of the sand filter. When the pressure difference exceeds 25 bar, a backwash procedure must be performed.

The frequency of backwashing the sand filter depends on the suspended solids content in the incoming water. When backwashing, first use an air pump for air washing, and then use a pump for flushing. The filtration accuracy of the sand filter is 50 μ m. After passing through the sand filter, the raw water directly enters the core filter. The equipment is equipped with two core filters, both of which have pressure gauges at the inlet and outlet ends. When the pressure difference exceeds 20 bar, the filter element should be replaced. The precision of the core filter is 10 μ m, providing the last protective barrier for the membrane column.

In order to prevent various insoluble sulfates and silicates from scaling in membrane components due to high concentration, and effectively extend the service life of the membrane, a certain amount of scale inhibitor needs to be added before the first stage reverse osmosis membrane. The amount added is determined based on the concentration of insoluble salts in the original water.

The raw water passing through the core filter directly enters the first stage reverse osmosis high-pressure plunger pump. There is a shock absorber behind each plunger pump in the DT membrane system, which is used to absorb the pressure pulse generated by the high-pressure pump and provide stable pressure to the membrane column. The effluent from the high-pressure pump enters the membrane module, which adopts a disc tube reverse osmosis membrane column. The membrane module has the advantages of strong anti pollution and good material exchange effect, and has strong adaptability to leachate. The first stage DTRO membrane has a lifespan of more than 3 years, and the second stage DTRO membrane has a lifespan of up to 5 years. The first level reverse osmosis system is planned to have two groups connected in series. The concentrated solution from the first group of reverse osmosis will enter the second group after being connected in series. The COD concentration and salt content of the concentrated solution treated in each group will increase sequentially. Set up a group for secondary reverse osmosis.

The water from the shock absorber of the first stage reverse osmosis enters the first membrane group, which is directly supplied with water by a high-pressure pump. The second group of membrane columns is equipped with an online circulating pump to generate sufficient flow rate and velocity to overcome membrane fouling; The second stage reverse osmosis does not require an online booster pump, as its inlet conductivity is relatively low and the recovery rate is relatively high. Only using a high-pressure pump can meet the requirements.

The water content of the membrane column assembly is divided into two parts. The permeate of the first stage reverse osmosis is discharged to the inlet of the second stage reverse osmosis, and the concentrated solution is discharged into the concentrated solution storage tank. The permeate from the second stage reverse osmosis enters the clean water storage tank and is waiting for reuse. The concentrated solution enters the inlet of the first stage reverse osmosis for further treatment. There is a pressure regulating valve at each concentration end of the two-stage reverse osmosis system, which is used to control the pressure inside the membrane group to generate the necessary water recovery rate.

(3) Clear water degassing and pH adjustment

Due to the presence of certain dissolved gases in high concentration wastewater, reverse osmosis membranes can remove dissolved ions but cannot remove dissolved gases, which may result in the pH value of the water produced by reverse osmosis membranes being slightly lower than the discharge requirements. After removing the acidic gases dissolved in the permeate through the degassing tower, the pH value can significantly increase. If the pH value of the clear water after passing through the degassing tower is still lower than the discharge requirement, the system will automatically add a small amount of alkali to adjust the pH value to the discharge requirement. Since the effluent is treated by degassing through the degassing tower, only a small amount of alkali solution needs to be added to meet the discharge requirement.

The pH adjustment of the effluent is carried out in the clear water tank, and a pH sensor is installed in the clear water discharge pipe. The PLC determines the pH value of the effluent and automatically adjusts the frequency of the metering pump to adjust the alkali dosage, ultimately making the pH value of the effluent meet the discharge requirements.

(4) Equipment flushing and cleaning

The cleaning of membrane groups includes two methods: rinsing and chemical cleaning.

The reverse osmosis system includes cleaning agent A, cleaning agent B, scale inhibitor, and cleaning buffer tank. Operators need to regularly add cleaning agents and scale inhibitors to the storage tank, set the cleaning execution time, and when cleaning is needed, the system will automatically perform system flushing:

The flushing of the membrane group is carried out every time the system is shut down. When it needs to be shut down under normal startup operation, the flushing first and then shutdown mode is generally adopted. When the system malfunctions, it automatically shuts down and also executes the flushing program. The main purpose of flushing is to prevent pollutants in the raw water from depositing on the surface of the membrane. There are two types of flushing: one is flushing with raw water, and the other is flushing with clean water. The flushing time for both types can be set on the operation interface, usually 2-5 minutes.