Are you need Membrane solutions? Free For Business

STRO Pipeline based Reverse Osmosis Membrane - High magnification Concentration of High Salt Wastewater

STRO membrane is a new type of high-pressure pipe network reverse osmosis membrane developed for the concentration, recovery, and standard discharge of high concentration, high salinity, and low suspended solids wastewater.

STRO membrane element combines the advantages of open channel and roll element design in its design, and is a new type of roll membrane element with a special 45 ° double-layer open channel structure.

The reverse osmosis membrane module is the most important component in the reverse osmosis unit. The Shannel Tube (ST) reverse osmosis membrane module combines the advantages of open channel and roll type membrane module design, with narrow and open channels, overcoming the shortcomings of other ordinary reverse osmosis membrane modules, greatly optimizing fluid dynamics performance, and greatly reducing common pollution and scaling problems in other reverse osmosis membrane modules.

The main components of the Shannel Tube (ST) assembly are membrane elements, pressure vessels, and two terminal flanges. The main components of a membrane element are the membrane, the water production grid (i.e. the water flow channel), and the inlet grid (i.e. the water flow channel). Every two sheets of film are laser welded to form a film pad with the production water separation network. Each film pad is separated from nearby film pads by an inlet grid, and multiple film pads and inlet grids are sequentially spiral wound to form a film element.

The development mechanism of most anti pollution products worldwide mainly starts from two aspects: first, the research and development of flat film; The second is the process of rolling membrane components. The development direction of flat film includes changing the surface charge, smoothness, hydrophilicity, etc. of the film; The direction of research and development in the rolling process includes changing the thickness of the water supply channel, altering the shape and angle of the water supply mesh, and increasing the number of membrane blades.

The specific improvements of the Shannel Tube (ST) component are reflected in the following aspects.

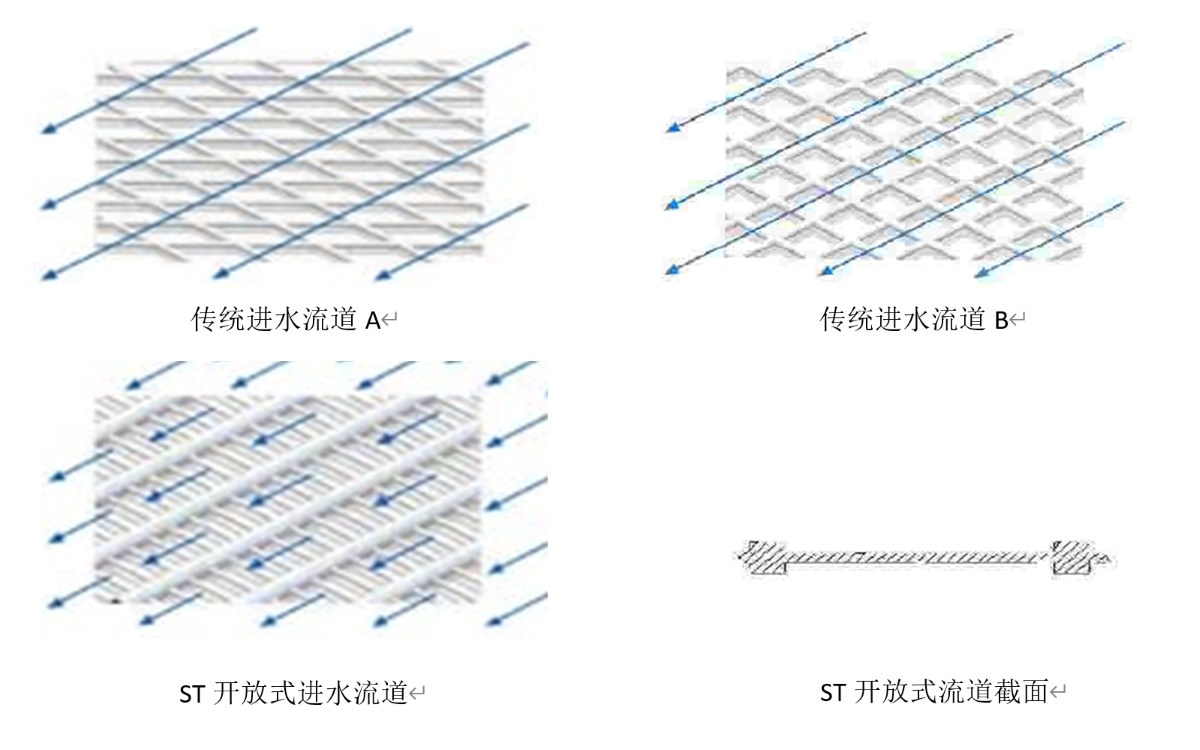

1) Improvement on the water supply channel

Among the many anti pollution mechanisms, the width of the water supply channel of reverse osmosis membrane elements is widely recognized as the most important indicator of the anti pollution performance of membrane elements, and it is also a key consideration for users when choosing products.

ST membrane components are roll type membranes, but they differ from traditional roll type membranes. The problem with traditional roll type membranes is that their mesh is prone to clogging and scaling, which limits the inlet flow channel and increases the pressure difference. In response to this issue, the ST membrane element combines the advantages of open channel and roll element design to obtain a membrane element with a narrow and open channel structure. This design greatly optimizes the effective area of the inlet channel and membrane, greatly alleviating the shortcomings of traditional roll up membranes.

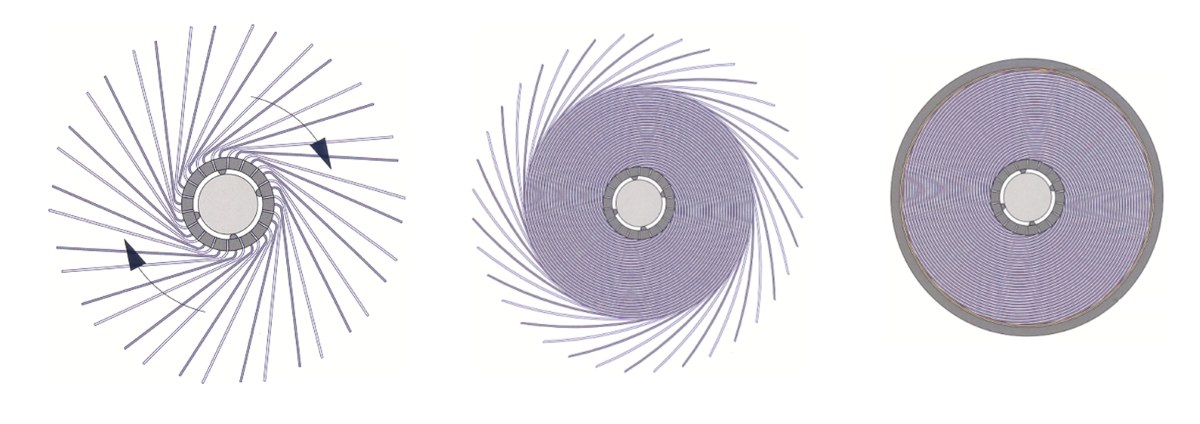

2) Improvement in Rolling Method

STRO reverse osmosis membrane has been improved in the rolling method: the blades have been shortened and the number of blades has been increased. Its advantages lie in:

① Shortened the length of freshwater channels and reduced pressure loss in freshwater channels;

② So that the net pushing pressure along the membrane tends to be the same;

③ Try to maintain equal water flux at different locations on the membrane surface;

④ Reduce the degree of concentration polarization.

Advantages of Shannel Tube (ST) component

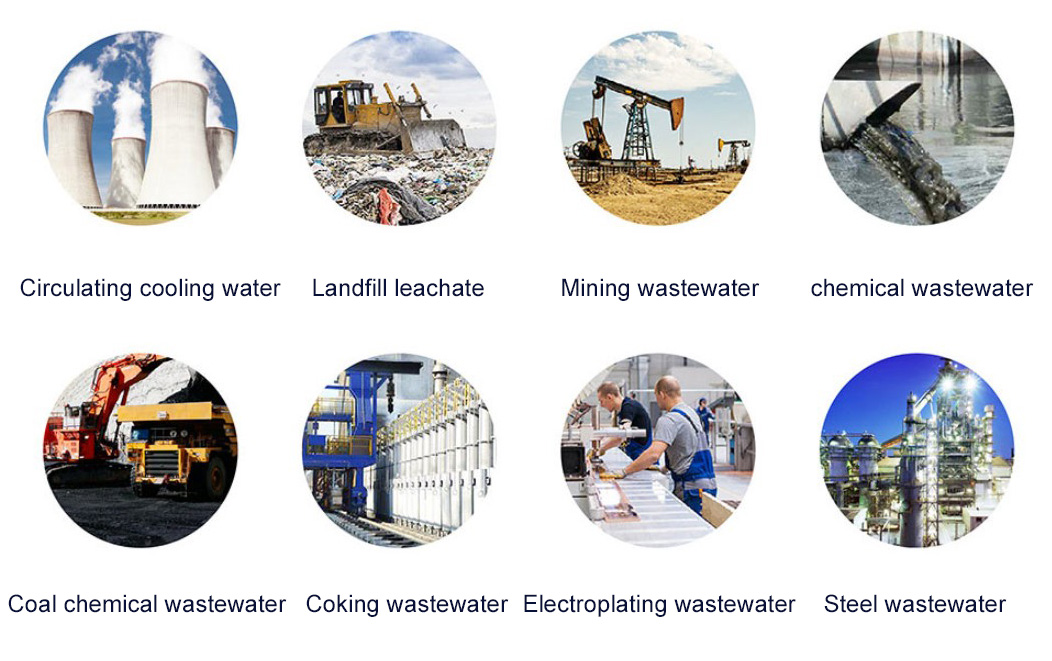

STRO components, as revolutionary reverse osmosis membrane products, are particularly suitable for concentration, recovery, and standard discharge of high concentration and high salt wastewater. It has an extremely wide range of adaptability to incoming water sources and unparalleled advantages in anti pollution performance.

1) The extremely high tolerance to incoming water quality is shown in the table below.

Number Water Quality Project Unit Value Remarks

| Number | Water Quality | Project Unit | Value | Remarks |

| 1 | COD | mg/l | ≤ 2000 | |

| 2 | Ammonia nitrogen | mg/l | ≤ 1000 | |

| 3 | SDI5 | / | ≤20 | |

| 4 | Conductivity | μ S/Sm | ≤ 30000 |

Unit removal rate of water quality project (%)2) Excellent removal effect on various chemicals in the incoming water

| Number | Water Quality | Project Unit | Value | Remarks |

| 1 | COD | mg/l | ≥95 | |

| 2 | Ammonia nitrogen | mg/l | ≥90 | |

| 3 | Sodium chloride | mg/l | ≥95 | |

| 4 | Heavy metals | mg/l | ≥95 |

The packing density of the membrane is high, the equipment takes up less space, and the engineering cost is reduced;

High desalination rate and stable performance, better product water quality, achieving higher water use indicators;

Special fluid hydraulic design reduces concentration polarization, improves fouling and scaling trends;

Open channel design for better cleaning effect and easier performance recovery;

The small number of seals makes maintenance easier.

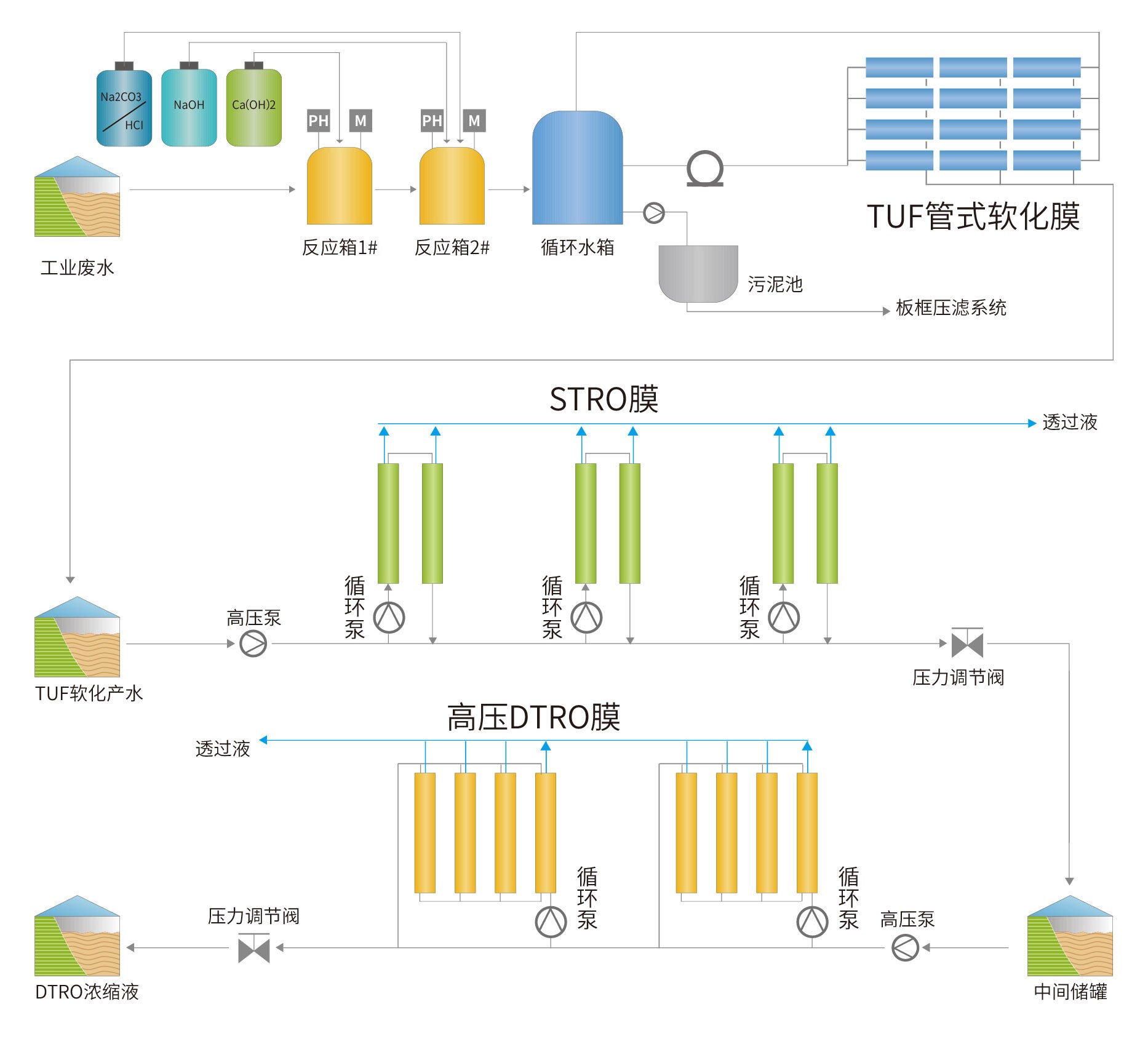

Introduction to STRO membrane process

1) Not dependent on preprocessing, with good stability, security, and adaptability

2) The flow rate/pressure of the device is automatically controlled. At any time, it can provide the maximum working capacity with the inlet water temperature and salinity;

3) Membrane components have less fouling, less membrane fouling, and longer membrane lifespan;

4) All units are equipped with a fail safe system that can prevent potential damage from external conditions and operational errors;

6) For each normal system shutdown, all components in contact with the raw water are flushed clean by the produced water due to the fully automatic "stop&flush" mode. It can prevent any organic/microbial contamination during equipment shutdown for up to 2 weeks without the need for chemical disinfection;

7) The high-pressure plunger pump starts running under initial conditions. Due to organic fouling or changes in TDS of the inlet water, in order to ensure that the reverse osmosis water production is controlled at the design value, the automatic pressure control valve slowly adjusts to continuously adjust the inlet pressure of the membrane to adapt to the operating pressure required for the design water production;

8) The design of detachable membrane module units makes maintenance of the components easy; A highly automated design makes operation easier and allows inexperienced personnel to perform maintenance and operation.

9) The system installation and maintenance are simple, the operation is convenient, the automation level is high, the scalability is strong, and it has a very reliable processing effect. The equipment is movable and saves land.

STRO Pipeline based Reverse Osmosis Membrane - Characteristics

High desalination rate:

Under standard testing conditions, the desalination rate reaches 99%, and the performance is stable. The product water quality is better, achieving higher water use indicators.

Anti pollution blockage:

Special fluid hydraulic design reduces concentration polarization, improves fouling and scaling trends.

Special flow channel:

Adopting a 45 ° diamond shaped double-layer flow channel design, the cleaning effect is better and the performance recovery is easier.

Easy to maintain:

Adopting a modular design with 1-6 units that can be assembled in series, it is easy to clean and maintain.

Small footprint:

High membrane packing density, smaller equipment footprint, and reduced project cost.

Small footprint:

The number of seals is small, maintenance is easier, service life is extended, and replacement costs are greatly reduced.

STRO Pipeline based Reverse Osmosis Membrane - Comparison

Comparison of water supply channels

The traditional roll type membrane mesh is prone to clogging and scaling, which limits the inlet flow channel and increases the pressure difference.

The STRO pipeline type reverse osmosis membrane has a 45 ° diamond shaped double-layer open channel structure, which greatly optimizes the effective area of the inlet channel and membrane, and makes the pressure more stable.

Comparison of Rolling Methods

STRO reverse osmosis membrane shortens the blades while increasing the number of blades, shortens the length of the freshwater channel, reduces the pressure loss of the freshwater channel, and the net pushing pressure along the membrane tends to be the same, which can maintain the same water flux at different parts of the membrane surface as much as possible, thereby reducing the degree of concentration polarization.

STRO Pipe Network Reverse Osmosis Membrane - Parameter Details

| Technical parameter | Unit | STRO-25-90 bar | STRO-27-90 bar | STRO-27-120 bar | STRO-27-120 bar |

| Inlet flow rate | m3/h | 4-8 | 5-12 | 4-8 | 5-12 |

| Maximum cleaning temperature | ℃ | 45 | 45 | 45 | 45 |

| Maximum operating temperature | ℃ | 40 | 40 | 40 | 40 |

| Maximum operating pressure | bar | 90 | 90 | 120 | 120 |

| Normal operating pressure | bar | 40-80 | 40-80 | 60-110 | 60-110 |

| Total length A | mm | 1200 | 1400 | 1200 | 1400 |

| Membrane module diameter B | mm | 218 | 218 | 244 | 244 |

| Membrane area | ㎡ | 25 | 27 | 25 | 27 |

| Normal membrane pressure difference | bar | 0.5-0.7 | 0.5-0.7 | 0.5-0.7 | 0.5-0.7 |

| 25 ° standard desalination rate | / | ≥98.5% | ≥98.5% | ≥97.5% | ≥97.5% |

If you have any questions or needs, please contact us

Address: No. 1206, No. 66 Yuandong Avenue, Gaocheng Town, Yixing City, China

Phone: +86 18915298518 (Whatsapp)

Email: wxflistec@gmail.com