Are you need Membrane solutions? Free For Business

1. MBR membrane introduction:

Membrane bioreactor (MBR) utilizes the selective permeability of membranes to achieve biological enrichment in aeration tanks, greatly improving the efficiency of biological treatment. The wastewater after biological treatment is separated by membranes to obtain cleaner effluent. He is an important technology for protecting water environment and realizing sewage resource utilization.

The working principle of membrane bioreactor (MBR) is to first remove biodegradable organic pollutants and other pollutants such as ammonia nitrogen from water through high concentration activated sludge, and then use a membrane to separate the purified water and activated sludge into solid and liquid.

The research on membrane bioreactor (MBR) for wastewater treatment began in the late 1960s and early 1970s. After entering the 1980s, it began to be applied in practical engineering. In the 1990s and earlier, due to limitations in technological development, the development and application of MBR were greatly restricted. After entering the 1990s, MBR began to enter the practical stage. The construction investment of MBR membranes has significantly decreased, and the emergence of integrated and suction MBR has greatly simplified the operation and management of MBR. MBR has been widely used in developed countries, and since the 21st century, its application in sewage treatment has entered a period of rapid development.

2. Characteristics of membrane bioreactor

1. Membrane bioreactor (MBR) can maintain a high concentration of microorganisms in the system. Due to the membrane's interception effect, the biological concentration in the biological phase is very high, reaching over 10000mg/l. This not only improves the overall removal efficiency of the reaction device for pollutants and ensures good effluent quality, but also makes the entire device highly resistant to various changes in influent load (water quality and quantity), and can stably obtain high-quality effluent quality.

2. Due to the membrane separation technology used in the separation of sludge and water after biological treatment, there is no need to worry about the problems of filamentous bacteria proliferation, sludge flotation, and loss that may occur with traditional biotechnology.

3. Excellent effluent quality from membrane bioreactor (MBR)

Membrane bioreactors can achieve biological enrichment and co metabolism. It can intercept microorganisms with longer generation cycles in sewage, such as nitrifying bacteria, and effectively degrade ammonia nitrogen in water. The collective metabolic process of a large number of microorganisms gathering together can lead to the degradation of some organic compounds that are difficult to biodegrade.

4. Membrane bioreactor (MBR) has low residual sludge production, does not produce chemical sludge, and has no secondary pollution

Membrane bioreactor can operate under high volume load and low sludge load, with low residual sludge production (theoretically achieving zero sludge discharge), reducing sludge treatment costs and potential pollution diffusion during sludge disposal.

5. Membrane bioreactor (MBR) occupies a small area and is not limited by the installation site

The membrane bioreactor can maintain a high concentration of microbial biomass, with a high volumetric load on the treatment device and a large footprint, resulting in significant cost savings; This process is simple, compact in structure, and occupies a small area. It is not limited by the installation location and is suitable for any occasion. It can be made into ground, semi underground, and underground types. For newly built sewage treatment plants, their land area is about 1/3 to 1/5 of traditional processes, which can save limited land;

6. Membrane bioreactor (MBR) is easy to operate and manage, and is easy to achieve automatic control

The membrane bioreactor achieves complete separation of hydraulic retention time (HRT) and sludge retention time (SRT), making operation control more flexible and stable. It is a new technology that is easy to equip in sewage treatment and can achieve fully automatic unmanned operation, making operation management more convenient.

7. Membrane bioreactor (MBR) is easy to integrate with traditional processes

Membrane bioreactor can be organically combined with conventional biochemical treatment processes. For example, as long as conditions permit, adding membrane components to the sedimentation tank in conventional biochemical treatment processes can be reasonably modified, greatly improving the effluent quality.

Comparison Table between Traditional Wastewater Treatment Processes and Membrane Bioreactors (MBR):

project

| Serial number | Traditional sewage treatment process | Membrane bioreactor (MBR) |

| 1 | Low MLSS (3-5mg/l) | High MLSS (10-20mg/l) |

| 2 | The sludge has a short age and is not suitable for control | The sludge has a long age and is completely under control |

| 3 | Only bacteria with fast reproductive rates can be cultivated | Various suitable microbial communities can develop and grow |

| 4 | Only bacteria capable of forming bacterial colonies can be retained | Specific bacteria can develop well |

| 5 | Large footprint | Small footprint, only 1/3 to 1/5 of traditional craftsmanship |

| 6 | Large sludge production | Low sludge production |

| 7 | The effluent quality is not stable enough and can basically meet the discharge standards. However, the water quality does not meet the requirements for reuse and requires deep treatment. | Strong shock load resistance, good and stable effluent quality, high-quality effluent that can meet the requirements for reuse. |

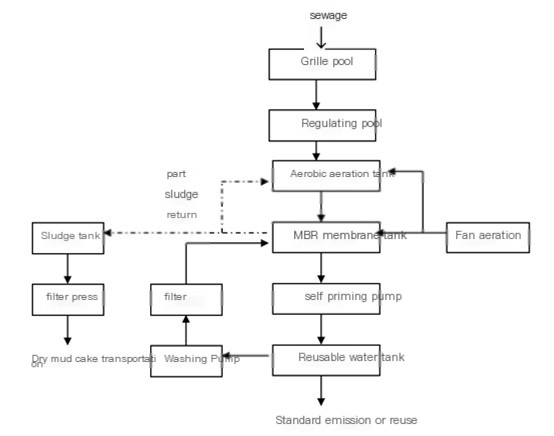

3. Membrane bioreactor process flow:

4. Performance characteristics and parameters of FLISTEC membrane materials

1. Advantages of membrane materials

In order to ensure the excellent performance of the membrane, it is necessary to control the surface characteristics and supporting structure of the membrane during the production process of ultrafiltration and microfiltration membranes. At the same time, the membrane material must also have good mechanical properties to ensure that the produced membrane has high strength and flexibility. Moreover, the membrane material should also have excellent chemical resistance.

The biggest characteristic of polyvinylidene fluoride is its extremely high chemical stability. And chemical stability determines its outstanding antioxidant capacity and acid alkali resistance. The most common and headache inducing problem encountered during the application of membranes is membrane fouling and blockage. During the water treatment process, microorganisms and organic matter in the water (especially in wastewater) often adhere to the surface of the membrane. As the membrane is used for a longer period of time, these substances will gradually block the membrane pores. This resulted in a direct decrease in membrane separation capability. To ensure the normal operation of the membrane and stable water flux, it is necessary to regularly clean the membrane. The most effective method to remove these microorganisms and organic matter adsorbed on the membrane surface is through oxidant cleaning. But oxidants can cause damage to many membranes. The ability of polyvinylidene fluoride (PVDF) to withstand oxidants (such as sodium hypochlorite) is more than 10 times that of materials such as polyethersulfone and polysulfone, greatly extending its service life.

Polyvinylidene fluoride also has strong flexibility. Flexibility is highly expected during the air scrubbing and cleaning process of membranes, therefore, polyvinylidene fluoride is widely used in membrane filtration forms that require air, such as membrane bioreactors (MBR) and membrane modules in external pressure filtration forms. The results of the actual case investigation indicate that polyvinylidene fluoride film has the lowest wire breakage rate.

Due to its extremely low breakage rate, high antioxidant capacity, high strength, excellent flexibility, and pollution resistance, polyvinylidene fluoride (PVDF) membrane has been increasingly widely used in the field of water treatment.

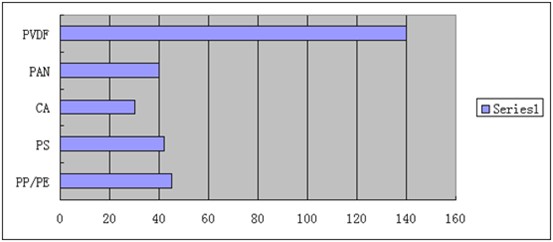

Comparison of toughness of various membrane materials

In summary, polyvinylidene fluoride film has the following advantages:

A: Strong chemical stability and high antioxidant capacity:

The high-quality polyvinylidene fluoride material determines the strong chemical stability of Jinhong products, and the high chemical stability of the membrane makes it resistant to high concentration oxidants for cleaning, effectively preventing the proliferation of bacteria and other microorganisms;

B: High flow rate: The product has a high porosity, allowing the components to have high flow rate:

C: High strength, high flexibility: Therefore, the membrane fibers have the lowest breakage rate. Flexibility is highly desirable in the air scrubbing and cleaning process of membranes, therefore, polyvinylidene fluoride membranes are widely used in membrane filtration forms that require air, such as membrane bioreactors (MBR) and external pressure filtration membrane components, to ensure low wire breakage rates;

D: Small nominal pore size: thus capable of removing almost all suspended particles, microorganisms, colloids, pathogens, and bacteria;

E: High pollution resistance: Through hydrophilic modification, the product's pollution resistance is greatly improved.

F: Long service life: Components usually adopt an external pressure structure that is not easily clogged, with a larger filtration area and higher interception capacity, easy to clean, and more thorough, which can timely remove membrane surface pollution and prolong the service life of the membrane.

G: High quality, high cost-effectiveness.

5. FLISTEC Curtain Membrane Basic Parameters Table and Membrane Component Usage Conditions

| Performance parameters | Membrane material | Polyvinylidene fluoride (PVDF) |

| Membrane pore size | 0.1 μm | |

| Hollow fiber membrane inner/outer diameter | 0.8/1.5 mm | |

| Material of water collection pipe | ABS pipe | |

| Fiber bonding material | epoxy resin | |

| Filter effects | Suspended solids>2 μm | 100% |

| Turbidity of produced water | ≤1 NTU | |

| Water Production SDI | ≤2.5 | |

| Microorganism | 99.999% | |

| Conditions of Use | Filtering method | outside-in |

| Working pressure | 0.01-0.05MPa (negative pressure) | |

| Operation temperature | 5-45℃ | |

| PH range during use | 2-11 (pH range 1-12 during cleaning) | |

| Oil content in raw water | <2 mg/L | |

| Maximum residual chlorine concentration in the inlet water | 200 mg/L (maximum residual chlorine concentration of cleaning agent 2000 mg/L) | |

| Suggested gas water ratio | 20:1-40:1 | |

| Design water production flux | 10-12 L/m2. h (selected based on inlet water quality) | |

| Online chemical cleaning | Online chemical cleaning frequency | Once a week to every three months (depending on specific water sources or determined by experiments) |

| Online chemical cleaning time | 120 minutes | |

| Online chemical cleaning agents | Liquid medicine: Sodium hypochlorite; Effective chlorine concentration: ≤ 2000 mg/L Liquid volume: 2L/m2 x membrane area+pipeline volume | |

| Immersion chemical cleaning | Immersion chemical cleaning frequency | From March to June (depending on specific water sources or determined by experiments) |

| Immersion chemical cleaning time | 2-6 hours | |

| Immersion chemical cleaning agents | Acid washing: 0.3-1% HCl or 1-2% citric acid Alkali washing: 0.1% NaOH+0.2% NaClO (effective chlorine) | |

| Cleaning solution temperature | 20-40 ℃ (higher temperature is beneficial for improving cleaning efficiency) |

6. Selection parameters for FLISTEC membrane MBR curtain membrane (submerged membrane)

| Component model | Type | Size(mm) | Membrane area (square) | Design flux (T/D) |

| FLISTEC-MBR-T10 | with inner lining reinforcement type | 535 * 1010 | 10 | 2-4 |

| FLITEC-MBR-T15 | with inner lining reinforcement type | 535 * 1500 | 15 | 3-6 |

| FLITEC-MBR-T20 | with inner lining reinforcement type | 535 * 2000 | 20 | 6-8 |

| FLITEC-MBR-10 | double-layer membrane | 535 * 1010 | 10 | 2-4 |

| FLITEC-MBR-15 | double-layer membrane | 535 * 1500 | 15 | 3-6 |

If you have any questions or needs, please contact us

Address: No. 1206, No. 66 Yuandong Avenue, Gaocheng Town, Yixing City, China

Phone: +86 18915298518 (Whatsapp)

Email: wxflistec@gmail.com